What type of shelves should be used in small and medium-sized factories?

Categories: Industry News

Release time: 2021-11-12

Cargo racking, generally refers to the placement of pallets, storage cages and other containers of shelves, from the mode of operation, cargo racking is generally through the forklift operation, in the design of the programme, usually we are able to calculate the number of shelves through the accommodation of the * large shelf storage, customers can be through the design of the number of ways to plan the storage of the warehouse.

Common types of bay racking are:

I Teardrop Selective Pallet Rack

Teardrop Selective Pallet Rack is a common type of racking, and is also a type of racking with a wide range of applications. Among all the racking type shelves, the cost of heavy duty shelves is * low, but the storage rate is also * low. It is suitable for warehouses with a wide variety of goods.

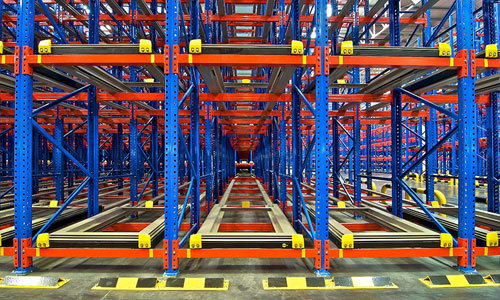

II Drive-Through Racking Systems

Drive-In Racking requires a single type of goods, which can be first in and last out of the goods. Drive-Through Racking Systems has higher requirements for forklift trucks, the width of the body cannot be too wide, and forklift trucks need to enter the access aisle. The storage rate of through-racking is higher, but the storage operation needs to enter the channel slowly, the efficiency is not too high.

III Gravity Racking

Gravity racking is a non-powered automatic type of racking that automatically slides down from a high place by the gravity of the goods. It has certain requirements on the material of pallet and the cost is higher. But the first-in-first-out, storage efficiency is high.

IV Radio Pallet Shuttle Rack System

Radio Pallet Shuttle Rack System consists of a shuttle car as a storage machine, through the forklift and shuttle car with the operation of the automated cargo space type racking. Radio Pallet

Shuttle Rack System is the future direction of the development of cargo space type racking, can be first in first out, if you want to achieve higher storage efficiency, need to be equipped with more shuttle car.

V Press-in shelving

Press-in racking, also known as push-back racking, pushes the trolley with the already placed goods to the rear by means of a forklift. This type of racking is generally chosen less.

Keywords: What type of shelves should be used in small and medium-sized factories?

RELATED NEWS

Company News

-

Different hole types of storage racking columns in the load-bearing capacity of each different

2024-06-13

-

Five key points of customised warehouse racking

2024-06-13

-

Warehouse shelves manufacturing process

2022-07-28

-

Warehouse racking installation construction process precautions

2021-11-12

-

Nantong heavy duty shelves should be selected correctly to ensure that the storage

2021-11-09