Products

As/Rs Automated Warehouses

- Commodity name: As/Rs Automated Warehouses

- Summary: Solid main structure, able to withstand the weight of large quantities of goods

- Load: 200kg~2000kg/space

- Material: Q235/Q345

- Material Thickness: 1.2mm~4.0mm

Service Hotline:

- Products

- Shelf Video

- General Parameters

- FAQ

- Shelf Case

-

As/Rs Automated Warehouses

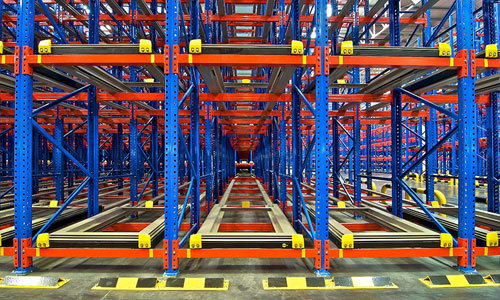

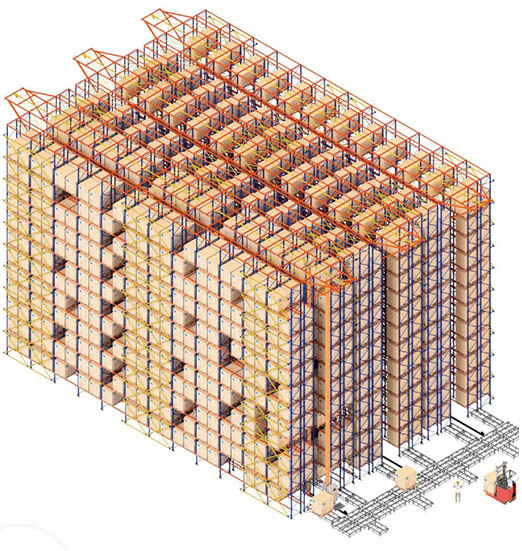

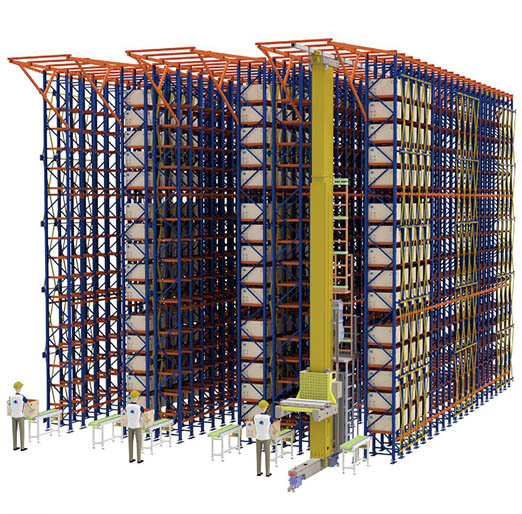

As/Rs Automated Warehouses is a multi-storey overhead structure used for storing goods in an automated three-dimensional warehouse. It is usually composed of steel or reinforced concrete structures, and is internally divided into standard-sized cargo spaces to accommodate the storage needs of goods of different sizes and weights. The main structure of the autostereoscopic warehouse shelves is solid, able to withstand the weight of a large number of goods and ensure the stability of long-term use. In addition to the shelves themselves, the autostereoscopic warehouse racking system also includes key equipment such as alley-type stacking cranes (also known as shuttle cars), entry (exit) workstations, and automatic transport in (out) and operation control systems. These equipments work together to achieve automatic access, handling and management of goods.

Pallet typeAs/Rs Automated Warehouses Box type As/Rs Automated Warehouses Product Features

1.As/Rs Automated Warehouses using multi-storey high rack design, can make full use of the vertical space of the warehouse, improve storage density. Compared with the traditional warehouse, its storage capacity is significantly improved, which helps enterprises to reduce storage costs.

2.Through equipment such as alley-type stacking cranes and automated conveyor lines, As/Rs Automated Warehouses is able to achieve automatic access and handling of goods. This not only improves operational efficiency, but also reduces labour costs and human error.

3.With the help of computer and bar code technology, intelligent warehouse management system and other advanced technical means, As/Rs Automated Warehouses can real-time monitoring of inventory, optimise the layout of goods and quickly respond to access instructions. This intelligent management improves the operational efficiency and accuracy of the warehouse.

4.As/Rs Automated Warehouses can be flexibly adjusted and expanded according to the actual needs of customers. For example, you can increase the number of shelves, adjust the size of the cargo space or upgrade the control system to meet the growing demand for storage.

Advantages of Pallet Type As/Rs Automated Warehouses

Advantages of box-type automated three-dimensional warehous

Improve warehousing efficiency and save logistics costs

Provide finite element analysis

Automatic production line

Pickling and Phosphating Spraying Line

Professional packaging and crating solutions

ISO9001 Quality Management Certification

Improve warehousing efficiency and save logistics costs

Provide finite element analysis

Automatic production line

Pickling and Phosphating Spraying Line

Professional packaging and crating solutions

ISO9001 Quality Management Certification

-

Load capacity 500kg~2000kg/space, customised on request Pick-up method Fully automated storage Product colour Orange, blue, grey, customizable Aisle Requirements No aisle is required, the shuttle car carries the goods and operates automatically in the rack. Warehouse Requirements No Requirements Scope of application Widely used in various industry sectors, such as manufacturing, retailing, pharmaceuticals, e-commerce, etc. Product Advantages Improve warehousing efficiency, save space resources, reduce manpower costs, and greatly improve the safety of cargoes. Product structure Shelf body + stacker + conveyor system + electrical control system + network + management system composition -

F:What are the terms of your deal?

Q:1.Payment terms: T/T 30% deposit upon order confirmation, 70% balance upon bill of lading. Or L/C.

2.Delivery time: normally within 30 days of receipt of deposit.

3.Sample Policy: Samples are always available for each model. Samples can be ready within 7-15 days after payment is received.

4.Port of shipment: Shanghai, China.

5.Discounts: We offer discounts for large quantities.

F:How do I deliver my goods?

Q:1.Sea freight: Once we know the seaport where you will deliver the goods, we will update the sea freight charges.

2.Customer Nominated Agent: Please let us know the contact information of your shipping agent and we will arrange for delivery of the items.

F:What are your services?

Q:1.We will respond to your inquiry about our products or prices within 24 hours.

2.Trained and experienced staff answer all your inquiries in fluent English.

3.OEM and ODM, any of your customized racks we can help you design your products.

4.We have experienced and professional engineers to provide the best solution.

F:How can I buy your products?

Q:Design drawing→Confirm drawing→Quotation→PI→Confirm PI→Arrange 30% deposit→Manufacturer→QC inspection→Payment of balance→Delivery

F:What are your strengths

Q:1.Warranty: one year warranty, damaged parts will be replaced and sent to you.

2.FACTORY PRICE: Factory direct competitive price.

-

Key words: