Products

Radio Pallet Shuttle Rack System

- Commodity name: Radio Pallet Shuttle Rack System

- Summary: A kind of multi-storey high-priced warehouse system used for storing goods

- Load: 200kg~2000kg/layer, can be customised as required

- Material: Q235/Q345

- Material Thickness: 1.0mm~4.0mm

Service Hotline:

- Products

- Shelf Video

- General Parameters

- FAQ

- Shelf Case

-

Radio Pallet Shuttle Rack System

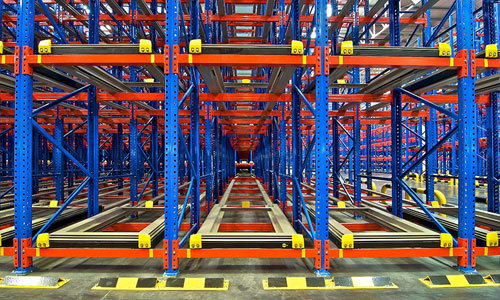

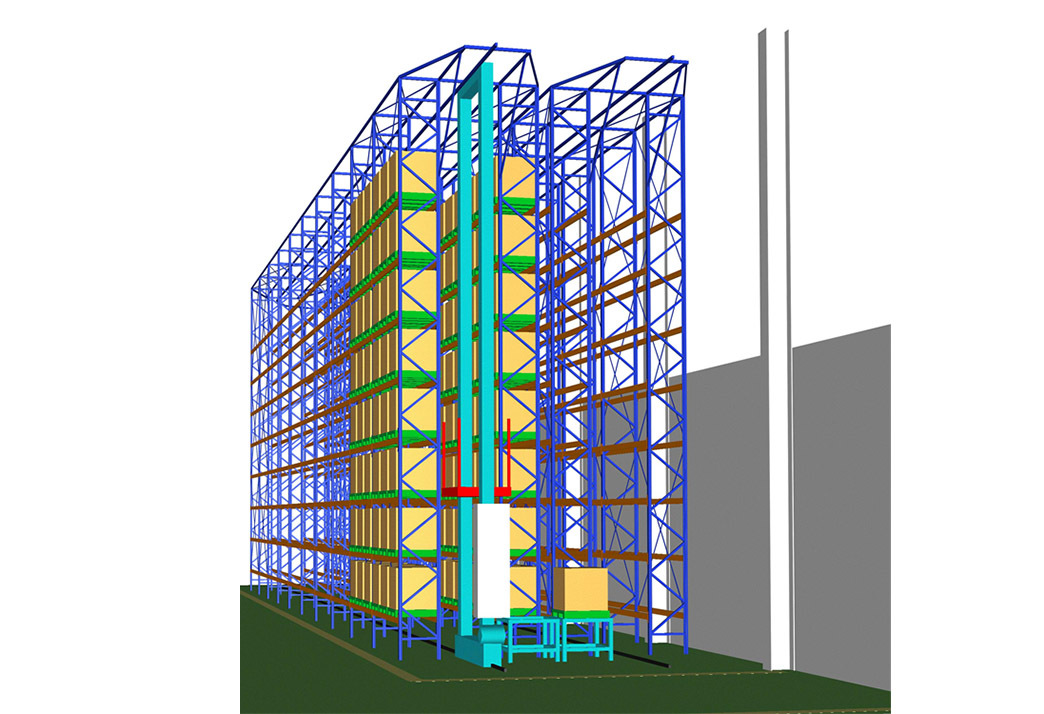

Radio Pallet Shuttle Rack System, also known as As/Rs Automated Warehouses, is a kind of multi-storey high-priced warehouse system used for storing goods, which consists of three-dimensional racking, stacker cranes, conveyors, handling equipment, pallet management information system and other peripheral equipment. It can automatically complete the storage operation of the goods according to the instruction, and can automatically manage the stock position, which plays a significant role in the modern enterprise.

Product Details

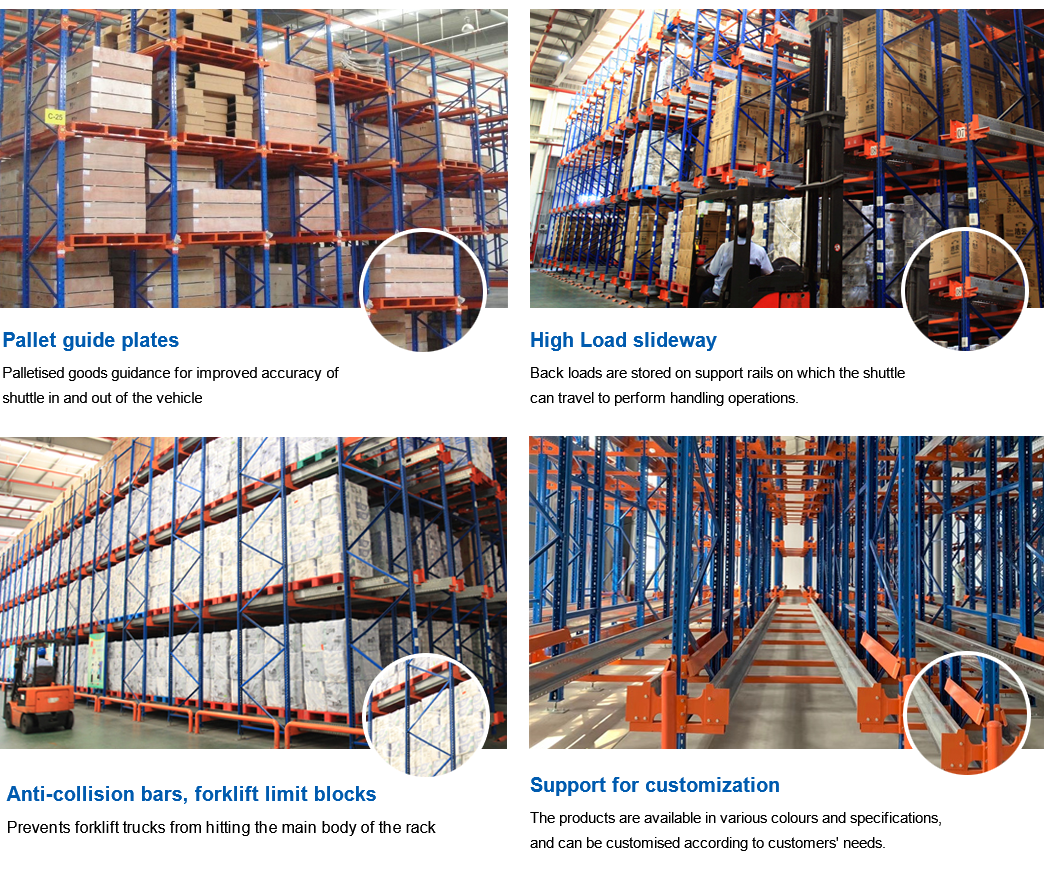

Product Features

Inventory: The goods are placed at the forefront of the racking aisle rails by forklift trucks, and the palletised goods are carried on the rails by radio-remotely operated shuttle trolleys;

Pick-up: Move the pallet deep in the shelf to the very front and remove the goods with the forklift;

Mobile trolley: Shuttle trolley is applied with different lanes, and the quantity is determined by the comprehensive factors such as the depth of the lane, the total amount of goods, the shipment batch, and the shipment frequency.

Scope of application

More quantity and less sample: food, beverage, chemical, tobacco and other single species in large quantities, relatively single phase of the industry.

Cold storage operations: Reducing the time spent working at low temperatures, improving operational efficiency and safety.

Deadline management: the item batch has strict requirements, the need for first-in-first-out management of the warehouse.

Increase capacity:Warehouses that have limited storage space and need to maximise the use of space.

-

-

Load capacity 500kg~2000kg/space, customised on request Pick-up method Shuttle + Forklift, Semi-automated Product colour Orange, blue, grey, customizable Aisle Requirements No aisle required, shuttle car carries goods and runs automatically in the shelves Warehouse requirement No requirement Scope of application Applicable in food, beverage, chemical industry, tobacco industry Product Advantages High efficiency storage, high space utilisation rate, high security of goods, good flexibility, scalable intelligent management Product Structure Shelf + Shuttle + Conveyor + Rail + Intelligent Control System -

F:What are the terms of your deal?

Q:1.Payment terms: T/T 30% deposit upon order confirmation, 70% balance upon bill of lading. Or L/C.

2.Delivery time: normally within 30 days of receipt of deposit.

3.Sample Policy: Samples are always available for each model. Samples can be ready within 7-15 days after payment is received.

4.Port of shipment: Shanghai, China.

5.Discounts: We offer discounts for large quantities.

F:How do I deliver my goods?

Q:1.Sea freight: Once we know the seaport where you will deliver the goods, we will update the sea freight charges.

2.Customer Nominated Agent: Please let us know the contact information of your shipping agent and we will arrange for delivery of the items.

F:What are your services?

Q:1.We will respond to your inquiry about our products or prices within 24 hours.

2.Trained and experienced staff answer all your inquiries in fluent English.

3.OEM and ODM, any of your customized racks we can help you design your products.

4.We have experienced and professional engineers to provide the best solution.

F:How can I buy your products?

Q:Design drawing→Confirm drawing→Quotation→PI→Confirm PI→Arrange 30% deposit→Manufacturer→QC inspection→Payment of balance→Delivery

F:What are your strengths

Q:1.Warranty: one year warranty, damaged parts will be replaced and sent to you.

2.FACTORY PRICE: Factory direct competitive price.

-

Key words: