Warehouse shelves manufacturing process

Categories: Company News

Release time: 2022-07-28

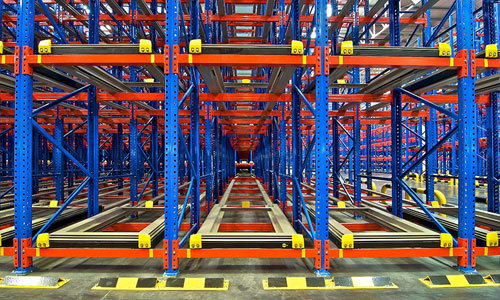

Warehouse shelving is an important part of modern logistics and warehouse management, its manufacturing process involves a number of links to ensure product quality and performance stability. The following is a detailed introduction to the manufacturing process of storage racks.

I. Demand analysis and design

1. According to the customer's demand, carry out product demand analysis to determine the type, specification and load capacity of the shelves, etc.

2. Design the structure of the shelves, including the selection of materials, size setting, connection methods, etc.

II. Procurement of raw materials

Procurement of required raw materials such as steel, connectors, coating materials, etc. based on design requirements.

III. blanking and cutting

Steel is undercut and cut using specialised equipment to ensure accurate dimensions.

IV. Moulding process

Including bending, punching, welding and other processes to form the basic frame of the shelf.

V. Surface treatment

1. the welded parts are treated with antirust treatment.

2. the surface of the shelf is polished to remove welding slag and burrs.

3. spraying treatment is carried out to enhance the corrosion resistance and aesthetics.

VI. Quality testing

1. carry out appearance inspection of the shelves to ensure that there are no obvious defects.

2. carry out load bearing test to ensure that the load bearing capacity of the shelves meets the design requirements.

VII. Assembly and commissioning

According to the design requirements, assemble each part of the shelf and debug it to ensure firm connection and smooth movement.

VIII. Packaging and storage

1.shelves are packed as necessary to prevent damage during transport.

2.stored in a warehouse awaiting despatch.

IX. Delivery and Installation

1.arrange delivery according to customer's demand.

2. install and debug to the best condition after arriving at customer's site.

X. After-sales service

After the products are sold, provide necessary after-sales service, such as repair and replacement.

The above is the manufacturing process of storage shelves. In the actual production process, it also needs to be adjusted according to the specific situation. Ensure that each link of rigour and refinement, is the key to the production of high-quality storage shelves. In order to meet the development needs of the modern logistics industry, the manufacturing of storage shelves is also constantly innovating and improving to improve its performance and adaptability. Manufacturers should pay attention to market dynamics and continue to develop new products to meet the diverse needs of customers.

Keywords: Warehouse shelves manufacturing process

RELATED NEWS

Company News

-

Different hole types of storage racking columns in the load-bearing capacity of each different

2024-06-13

-

Five key points of customised warehouse racking

2024-06-13

-

Warehouse shelves manufacturing process

2022-07-28

-

Warehouse racking installation construction process precautions

2021-11-12

-

Nantong heavy duty shelves should be selected correctly to ensure that the storage

2021-11-09